Yan Luo, Xiaoyan Liu*, Yu Fang*, Acc. Mater. Res., 2025, DOI: 10.1021/accountsmr.4c00400

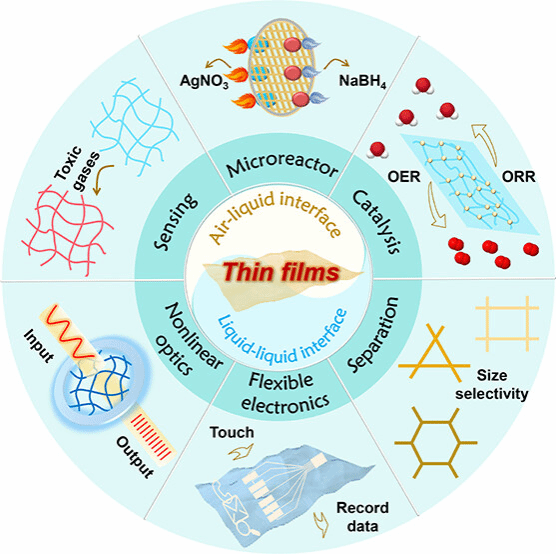

Figure 1. Preparation and application of functional thin films

Functional thin films prepared through interfacial polymerization (IP) have garnered significant attention due to their unique structural characteristics and wide-ranging application potential. These films are typically fabricated at air–liquid or liquid–liquid interfaces, which create distinctive environments conducive to polymerization and thin film formation. In the air-liquid interfacial polymerization (ALIP) process, reactive monomers self-assemble at the interface prior to polycondensation, allowing for the confined growth of two-dimensional materials. By carefully adjusting the monomer concentration, building block structure, and reaction time, it is possible to produce large-area, freestanding, defect-free thin films with a tunable thickness and porosity. These thin films exhibit strong adhesion, flexibility, and geometric continuity, making them particularly suitable for advanced applications in separation technologies, soft optics, catalysis, and environmental protection. Liquid–liquid interfacial polymerization (LLIP) further expands the range of building blocks available for thin film preparation. The interface between two immiscible liquids provides an ideal platform for reactive molecules residing in different phases to interact, facilitating the growth of large-area, uniform, free-standing films with extensive porosity. The properties can be finely controlled by varying the building block structure, monomer concentration, and reaction time, highlighting their potential for scalable production of functional thin films. The IP method effectively addresses challenges in thin film production such as substrate effects and mass transfer limitations, thereby enhancing the sensitivity and reliability of high-performance films. These advantages underscore the pivotal role of IP in the development of multifunctional thin films, offering distinct benefits over conventional top-down or bottom-up synthesis methods.

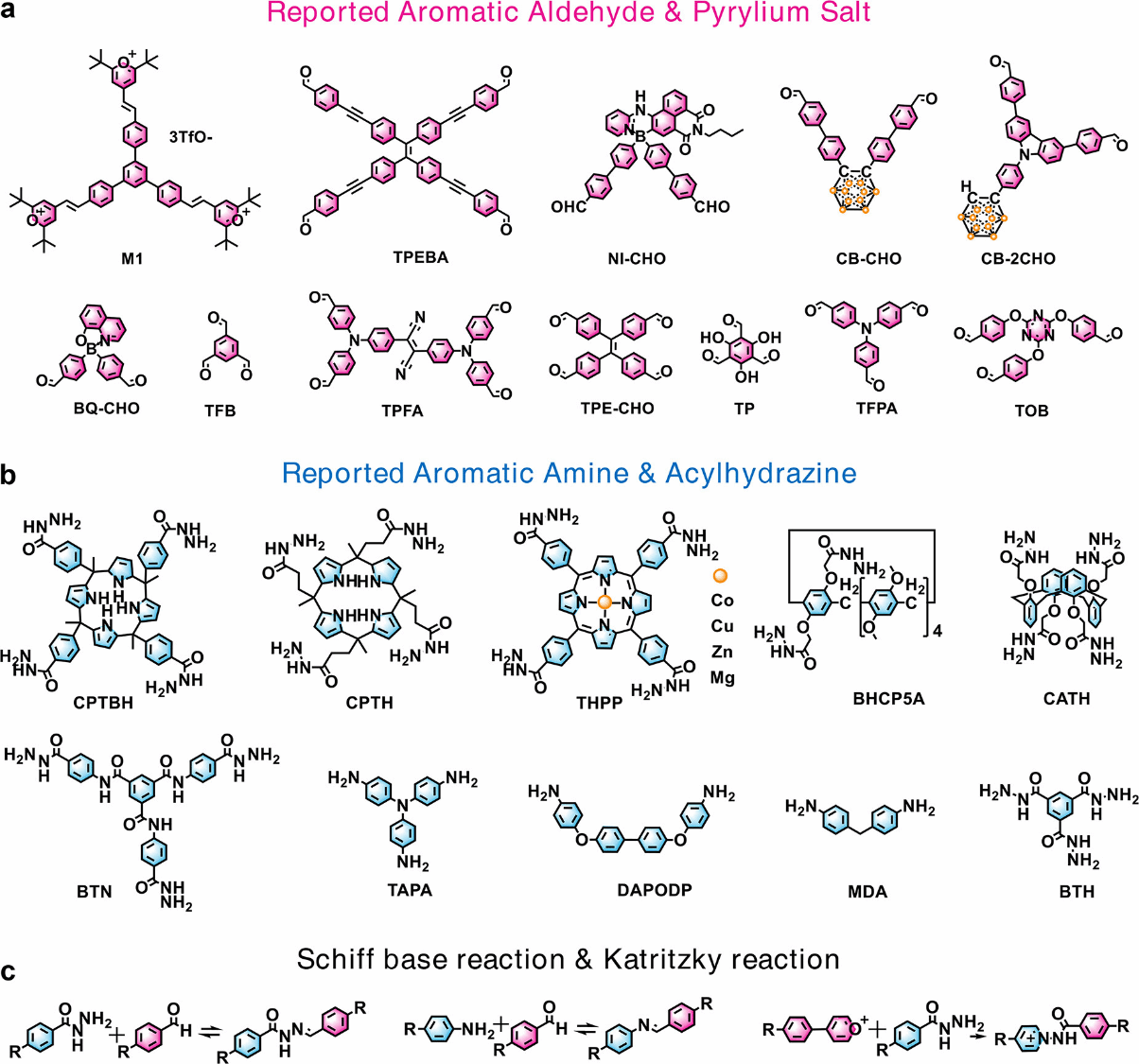

Figure 2. Typical molecular building blocks in the fabrication of thin films: (a) Aldehyde and pyrylium salt monomers, (b) amino and hydrazide monomers, and (c) typical linkage bonds of the thin films prepared through Schiff base and Katritzky reactions.

This Account presents recent research advancements achieved by our group in developing functional thin films via ALIP and LLIP. We first explore the preparation of various thin films with specific properties through Schiff base and Katritzky reactions. We then discuss their applications in fluorescence and colorimetric sensing, adsorption, separation, catalysis, soft actuators, flexible surface-enhanced Raman scattering (SERS) substrates, and nonlinear optics (NLO). Finally, we address the current challenges in developing interfacially confined films and propose future research directions aimed at advancing the innovation of thin films with unique physicochemical properties.

First Author: Yan Luo, doctoral candidate, Shaanxi Normal University

Correspondence Authors: Prof. Yu Fang and A/Prof. Xiaoyan Liu, Shaanxi Normal University

Full Text Link::https://doi.org/10.1021/accountsmr.4c00400